the jj mack building transformation

Where British Manufacturing Excellence Meets Heritage Architecture.

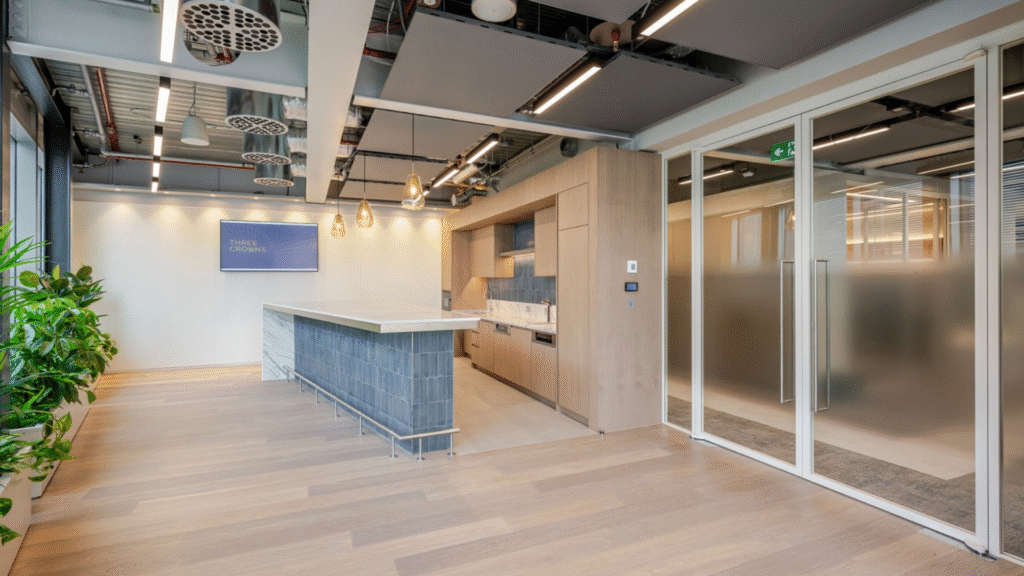

In the bustling heart of Smithfields, where London’s historic meat market has operated for over 800 years, a remarkable transformation has taken place within the walls of the JJ Mack Building. This August, we’re proud to spotlight our latest achievement at 33 Charterhouse Street, where City Concepts partnered with Overbury and MCM to deliver a sophisticated 16,000 square foot workspace that seamlessly blends contemporary acoustic performance with the character of this iconic London district.

The JJ Mack Building project represents more than just another successful installation – it exemplifies the precision, craftsmanship, and sustainable manufacturing practices that define British excellence in commercial glazing. Every partition, every door, and every acoustic solution was meticulously crafted at our UK headquarters, embodying our commitment to local manufacturing and environmental responsibility.

The Challenge. Complexity Vs. Co-ordination.

Working within the constraints of a busy commercial building during peak construction season presented unique challenges that demanded both technical expertise and logistical precision. Our six-week installation period coincided with the Christmas period, forming part of an intensive 18-week total construction programme that required seamless coordination with multiple contractors operating simultaneously within the building.

The project’s complexity extended beyond mere scheduling. The design called for a sophisticated dual-zone approach, with back-of-house areas requiring different aesthetic and functional specifications from the client-facing front-of-house spaces. This demanded not only technical versatility but also the kind of manufacturing flexibility that can only be achieved through local production and direct quality control.

British Manufacturing. The Foundation of Excellence at our HQ Facility.

At the heart of this project’s success lies a fundamental principle that sets City Concepts apart in an increasingly globalised marketplace: our unwavering commitment to British manufacturing. Every Concept screen and door system installed at the JJ Mack Building was manufactured at our UK headquarters, where decades of expertise in acoustic glazing converge with cutting-edge production techniques.

This local manufacturing approach delivers tangible benefits that extend far beyond mere patriotic sentiment. Our UK-based production facility enables rapid response to design modifications, ensures consistent quality control throughout the manufacturing process, and significantly reduces the carbon footprint associated with international shipping and logistics.

When challenges arose during the JJ Mack Building project – such as the need to machine Euro cylinders into our slim profile doors for enhanced security – our manufacturing team could respond immediately, adapting specifications without the delays typically associated with overseas production.

The sustainability implications of this approach cannot be overstated. By manufacturing locally, we eliminate thousands of miles of transportation, reduce packaging requirements, and maintain direct oversight of our environmental impact. Our UK headquarters operates under stringent environmental standards, ensuring that every product leaving our facility represents not just acoustic excellence but also responsible manufacturing practices.

Acoustic Performance Meets Aesthetic Sophistication

The JJ Mack Building installation showcased the full range of our Concept54 system capabilities, with the majority of the space featuring single glazed screens achieving 40dB Rw acoustic performance, complemented by Concept RS32c single glazed doors rated at 38dB Rw. For areas requiring enhanced acoustic isolation, we installed Concept54 double glazed screens delivering 46dB Rw performance, paired with Concept RD32 double glazed doors achieving 42dB Rw.

The aesthetic execution proved equally sophisticated, with back-of-house areas finished in Textured White RAL 9001 powdercoating, providing a clean, professional appearance that complements the building’s contemporary interior design. Front-of-house areas received our Light Bronze powdercoat finish, creating a warm, welcoming atmosphere that reflects the premium nature of the workspace while maintaining the acoustic performance standards demanded by modern commercial environments.

Door hardware represented another area where British manufacturing excellence proved invaluable. Each door was fitted with floor springs and pivots, complemented by back-to-back satin stainless steel mitred pull handles supplied by Franchi. The precision required to integrate these components seamlessly with our glazing systems demonstrates the level of coordination possible when manufacturing remains under direct control

Solving Complex Design Challenges

One of the project’s most technically demanding aspects involved the integration of security systems with our glazing solutions. Euro cylinders were precision-machined into our slim profile doors, providing clients with flexible locking options while maintaining the sleek aesthetic profile that defines our door systems. This customisation, achieved through close collaboration between our design and manufacturing teams, exemplifies the responsive approach possible through local production.

The coordination with access control systems at reception glazed doors required equally precise integration, ensuring seamless operation while maintaining security protocols. Such complex integrations demand not just technical expertise but also the kind of rapid communication and adjustment capability that local manufacturing makes possible.

Perhaps most challenging was the requirement to recess deflection heads within the plasterboard ceiling, creating a completely concealed installation that preserved the designer’s aesthetic vision. This demanded early coordination with the drylining contractor and precise manufacturing tolerances that could only be achieved through direct oversight of the production process.

The success of the JJ Mack Building project reflects the strength of our partnerships with Overbury and MCM, organisations that share our commitment to excellence and precision. Under the expert project management of Jake Charter, the collaboration demonstrated how effective communication and shared standards can overcome even the most complex logistical challenges.

Working alongside Overbury, a company renowned for their expertise in commercial fit-outs, provided the perfect complement to our glazing specialisation. Their understanding of the unique challenges presented by historic London buildings, combined with MCM’s technical expertise, created a collaborative environment where solutions could be developed and implemented with remarkable efficiency.

The period installation timeline, while challenging, showcased the dedication and professionalism of all partners involved. By maintaining open communication channels and flexible scheduling, the team ensured that the project progressed according to programme despite the seasonal constraints and the complexity of coordinating multiple contractors within the same building.

The JJ Mack Building project represents more than a successful installation—it demonstrates the continued relevance and superiority of British manufacturing in an increasingly complex commercial environment. As international supply chains face ongoing disruption and environmental concerns drive demand for local production, our commitment to UK-based manufacturing positions City Concepts at the forefront of industry evolution.

We extend our sincere appreciation to Overbury and MCM for their exceptional partnership throughout this project. Their professionalism, expertise, and collaborative approach made the JJ Mack Building transformation possible, and we look forward to future opportunities to work together on equally challenging and rewarding projects.

The success achieved at 33 Charterhouse Street stands as testament to what can be accomplished when British manufacturing excellence meets collaborative partnership and innovative design. As we continue to develop our capabilities and expand our sustainable manufacturing practices, projects like the JJ Mack Building installation remind us why local production, environmental responsibility, and technical excellence remain the cornerstones of our approach.

Collaborations:

Overbury Plc | Overbury

MCM Associates | MCM Architects

Franchi Glass | Franchi Glass

Photerior | Photerior

City Concepts specialises in acoustic glazing solutions for commercial environments, with all systems manufactured at our UK headquarters. For more information about our Concept54 range and sustainable manufacturing practices, visit www.cityconcepts.co.uk

The views expressed in this article are those of City Concepts and do not necessarily reflect the views of our partners or clients. All acoustic performance figures are based on laboratory testing and may vary depending on installation conditions.